ENGLISH

myPlant Performance*: Proven digital technology helps you increase unit efficiency and uptime

- Categories:Innovation to share

- Author:

- Origin:

- Time of issue:2022-04-07 17:57

- Views:

(Summary description)At first, it all seemed trivial -- tiny deviations from the engine's normal operation had gone undetected. You are lucky to have myPlant Performance*, INNIO's cloud-based asset Performance Management (APM) solution that gives you a whole new understanding of the operational Performance of The Yambach facility.

myPlant Performance*: Proven digital technology helps you increase unit efficiency and uptime

(Summary description)At first, it all seemed trivial -- tiny deviations from the engine's normal operation had gone undetected. You are lucky to have myPlant Performance*, INNIO's cloud-based asset Performance Management (APM) solution that gives you a whole new understanding of the operational Performance of The Yambach facility.

- Categories:Innovation to share

- Author:

- Origin:

- Time of issue:2022-04-07 17:57

- Views:

At first, it all seemed trivial -- tiny deviations from the engine's normal operation had gone undetected. You are lucky to have myPlant Performance*, INNIO's cloud-based asset Performance Management (APM) solution that gives you a whole new understanding of the operational Performance of The Yambach facility.

myPlant Performance* The benefits for your Yanbach generator set do not end there. With predictive monitoring of engine health, our proven technology helps you gain expert insights based on the condition of your equipment to optimize performance and avoid on-site inspections. With myPlant Performance*, you can increase plant operating efficiency, increase plant uptime, and reduce operating costs throughout the plant life cycle. You can manage your plant anytime, anywhere.

Our technology is proven and connected to over 18,000 devices... And it keeps increasing. That's more than 30 billion minutes of device monitoring, more than 1.7 million monitored sensors, more than 14 terabytes of data processed each year, and more than 70 preventive analytics methods.

Our technology is safe. Network and data security is the cornerstone of the business: thanks to our data security experts, all data transmitted is fully encrypted and protected, stored securely and cannot be accessed by third parties. In addition, we will continue to manage this data for you to prevent leaks.

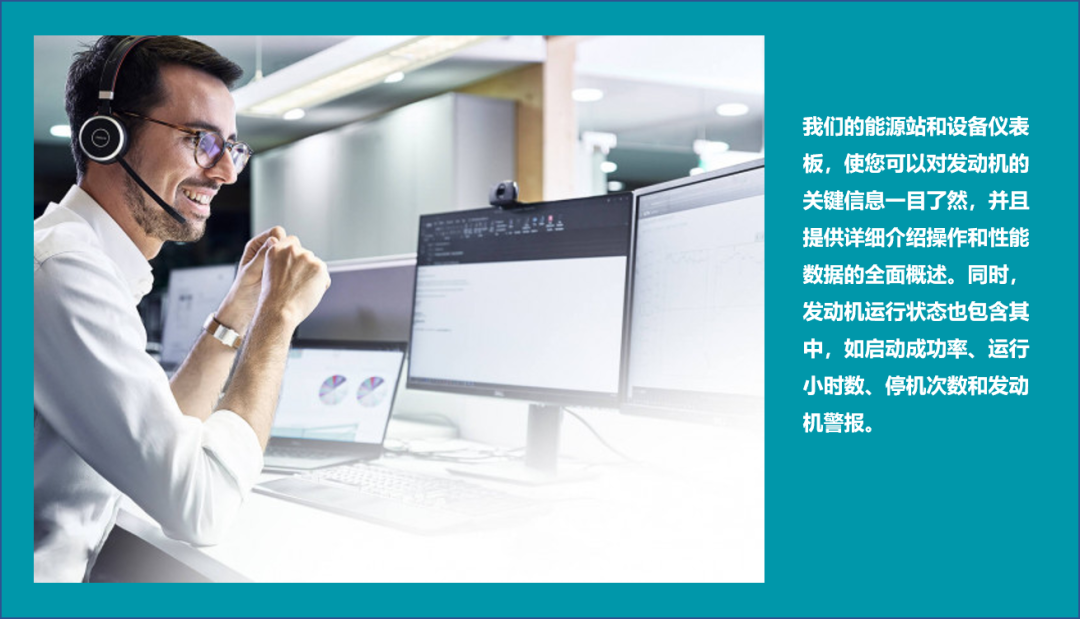

Our cloud-based myPlant APM solution allows you to manage your equipment safely and in real time, anytime, anywhere. You can easily access a centralized view of engine manuals, smart tools, and fleet data using your preferred customer terminal.

You can receive a brief overview of the engine fleet, as well as specialized reports (including alarms, power output, and other operational data) for further data exploration.

Automated email/SMS provides you with the operational data you need to early predict upcoming engine events. Customize your engine monitoring Settings to your business needs and create your own custom notification messages based on engine failure codes and operational data to enable customized monitoring.

Finally, myPlant Performance* consolidates business relevant information from multiple data sources, such as laboratory oil and coolant reports, engine documents and maintenance plans, into one platform.

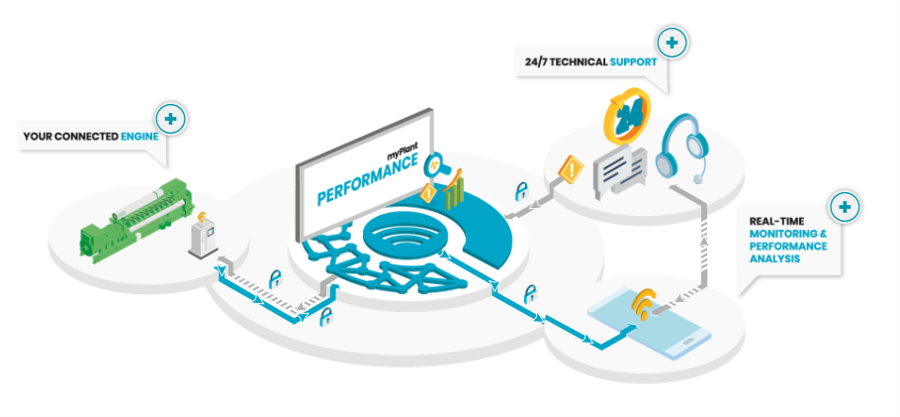

How does myPlant Performance* work?

First, we find deviations from the operating model. The myPlant Performance* algorithm continuously analyzes the data generated from your engine to detect any deviations that could lead to unexpected events. Based on data from thousands of engines across the globe, these algorithms define and identify patterns of healthy engine operation and record deviations when they occur.

Here, we'll help you take action before it happens. When a relevant deviation is detected, you will be notified immediately by email or SMS. Before an unplanned event occurs, you will be advised to take action.

Finally, we will predict the life of the part. Analytical algorithms are used to predict the service life of engine spark plugs, lubricants and filters. By getting this information in advance, you can save time and cost by replacing supplies only when necessary.

-

Digitisation makes your power station more future-proof and enables you to control engine performance more effectively.

-

We can remotely resolve more than 65% of engine failures, reducing travel and maintenance costs and increasing unit uptime.

-

Manage your engine in real time with your preferred client. MyPlant Performance* helps you stay one step ahead: Advanced algorithms constantly evaluate your engine data to detect the smallest operating deviations early and solve problems first.

Focused on your satisfaction, we will continue to work with you to improve our technology solutions. The latest features of our Yanbach myPlant APM solution include:

| Emission monitoring dashboard | This dashboard can be used if your Yambach engine is equipped with a nitrogen oxide sensor. Provides visual information on current average NOX values, which shows when unit emissions exceeded nox limits over the past 365 days, notifes you of relevant emissions warnings via SMS or email, and provides daily and monthly emissions data reports. |

| Lubricating oil analysis report | MyPlant has direct access to lubricant analysis reports thanks to cooperation with several specialized lubricant laboratories around the world. It then processes and details this information in a comprehensive overview showing the results of all historical lubricants analyses. In addition, based on the data received, myPlant will notify you when it detects a poor oil condition and remind you to arrange for oil sampling. |

| Custom event monitoring | Each power station has different unit monitoring requirements. MyPlant allows you to create custom events to track specific engine data and alerts. When set, these events can trigger notifications via SMS or email, are stored as historical data items, and appear on your alert overview page |

QUIK LINKS

CONTACT US

ADDRESS : Room 1505, Ruibao Oriental Mansion, Sanyi StreetNo.28-4, Hunnan District, Shenyang, Liaoning Province, China, 110180

PHONE : +86 24-31696477/6479

ADDRESS : No.200 Shifu Road, Heping District Shenyang City, China

PHONE : +86 24-23254798/4799/4800

Wechat scan

Follow the wechat official account