ENGLISH

-

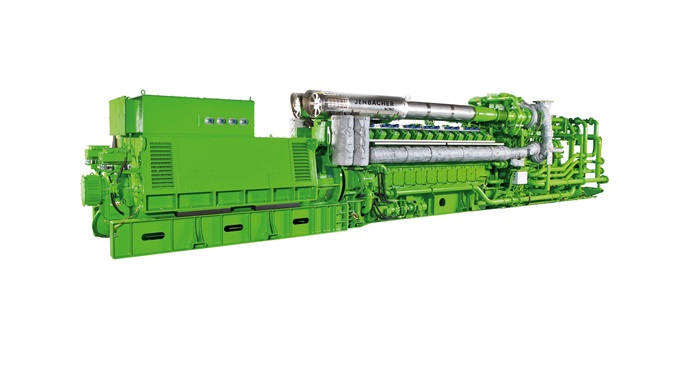

JENBACHER J624 6SERIES Gas combustion engine

- Based on his rich experience and continuous improvement, Yanbach has developed the 6 series of 1.8 to 4.5 MW reliable internal combustion engine products.

-

The crystallization of cutting-edge technology

Based on his rich experience and continuous improvement, Yanbach has developed the 6 series of 1.8 to 4.5 MW reliable internal combustion engine products. Its 1,500 RPM speed increases power generation density and reduces installation costs. The 6 series internal combustion engine is equipped with a precombustion chamber to maximize gas combustion efficiency, while reducing emissions. The proven design and optimized components enable the equipment to operate for 60,000 trouble-free hours prior to overhaul. The all-new J624 is equipped with two-stage turbocharging technology to provide greater efficiency and flexibility in response to changing environments.

Technical characteristics

| Characteristic | Instructions | Advantages |

| Four-valve cylinder head | A central purged precombustion chamber was designed using advanced computational tools and simulation techniques (CFD) |

- Reduce pressure exchange losses |

| Heat recovery | Lubricating oil heat exchanger can be two stage plate heat exchanger |

- Maximum thermal efficiency can be achieved even when the return water temperature is high or fluctuating |

| Air/gas mixer | Before entering the turbocharger, gas and air are mixed under low pressure conditions |

- The main gas supply can be done at low pressure |

| Gas distribution valve | High precision electronic control gas quantitative control valve (natural gas) |

- Quick response, air fuel faster than adaptation |

| Two-stage turbocharging | Latest turbocharging technology (available only) for J624 |

- Improve output power and efficiency |

Technical parameters

| Structure |

V 60° |

|||

|

The cylinder diameter (mm) |

190 |

|||

|

Sstroke (mm) |

220 |

|||

|

Displacement/cylinder (l) |

6.24 |

|||

|

Speed (rpm) |

1,500 (50 Hz) |

|||

|

Average piston speed (m/s) |

11 (1,500rpm ) |

|||

| Scope of supply | Generator set, combined heat and power system | |||

| The available gas | Natural gas, associated gas, biogas, Landfill gas, sewage biogas, special gas, (such as coalbed methane, coke oven gas, wood gas, high temperature cracking gas, etc.) |

|||

| Internal combustion engine model |

J612 |

J616 |

J620 |

J624* |

| Number of cylinders |

12 |

16 |

20 |

24 |

|

The total emissions (l) |

74.9 |

99.8 |

124.8 |

149.7 |

| Dimensions Length × width × height (mm) | ||

| Container configuration | J612–J620 |

12,000/15,000 x 3,000/ 6,000 x 8,100 |

| J624 | 17,000 x 6,000 x 8,400 | |

| Generating set | J612 | 7,600 x 2,200 x 2,800 |

| J616 | 8,300 x 2,200 x 2,800 | |

| J620 | 8,900 x 2,200 x 2,800 | |

| J624* | 12,800 x 2,500 x 2,900 | |

| Cogeneration system | J612 | 7,600 x 2,200 x 2,800 |

| J616 | 8,300 x 2,200 x 2,800 | |

| J620 | 8,900 x 2,200 x 2,800 | |

| J624* | 12,800 x 2,500 x 2,900 | |

|

Empty weight(kg) |

J612 |

J616 |

J620 |

J624* |

| Generating set |

24,000 |

29,200 |

36,900 |

52,100 |

| Cogeneration system |

24,500 |

29,700 |

37,500 |

52,100 |

| Dimensions and weight correspond to 50HZ products | ||||

Output and efficiency

| Natural gas |

1,500 rpm | 50 Hz |

|||||

|

NOx < |

Type |

Pel (kW)1 |

ηel (%)1 |

Pth (kW)² |

ηth (%)² |

ηtot (%) |

|

500mg/Nm3

|

J612 | 2,004 | 45.0 | 1,930 | 43.3 | 88.3 |

| J616 | 2,678 | 45.5 | 2,527 | 42.9 | 88.4 | |

| J620 | 3,360 | 45.6 | 3,172 | 43.0 | 88.6 | |

| J624 | 4,500 | 46.4 | 4,230 | 43.6 | 90.0 | |

|

250mg/Nm3 |

J612 | 2,004 | 44.2 | 1,936 | 42.7 | 86.9 |

| J616 | 2,678 | 44.7 | 2,548 | 42.5 | 87.2 | |

| J620 | 3,360 | 44.8 | 2,977 | 39.7 | 84.4 | |

| J624 | 4,500 | 45.4 | 4,314 | 43.5 | 89.0 | |

| Biogas |

1,500 rpm | 50 Hz |

|||||

|

NOx < |

Type |

Pel (kW)1 |

ηel (%)1 |

Pth (kW)² |

ηth (%)² |

ηtot (%) |

|

500mg/Nm3 |

J612 | 2,000 | 44.4 | 1,827 | 40.6 | 85.0 |

| J616 | 2,676 | 44.6 | 2,433 | 40.5 | 85.1 | |

| J620 | 3,352 | 44.7 | 3,034 | 40.4 | 85.1 | |

|

250mg/Nm3 |

J612 | 1,820 | 43.0 | 1,717 | 40.6 | 83.6 |

| J616 | 2,435 | 43.2 | 2,292 | 40.6 | 83.8 | |

| J620 | 3,054 | 43.3 | 2,863 | 40.6 | 83.9 | |

1) Technical parameters according to ISO3046 standard.

2) The total thermal output error is +/ -8%, the exhaust gas emission temperature is 120˚C, and the biogas emission temperature is 180˚C.

All data is obtained when the equipment is at full capacity and is subject to change and improvement as technology develops.

More models are available upon request

| J624 Two-stage turbo Charged Shanghai International Tourism Resort Shanghai, China | |||||

| Fuel | The unit type | Electric power output | Thermal power output | Dispatch Date |  |

| Natural gas |

5*J624 双级 |

22,000 kW |

20,070 kW |

11/2014 | |

|

Completed in 2014, Shanghai Tourism Resort is a comprehensive resort integrating large-scale entertainment, retail, catering, accommodation and shopping. Disneyland is located in the resort. Gas distribution including 5 Yanbach J624 two-stage turbocharged gas units and other key equipment The energy station provides a variety of clean energy for the core area of the resort, such as cold, heat, electricity and compressed air, in terms of efficiency, energy saving and so on Emission reduction has been greatly improved compared with traditional methods. |

|||||

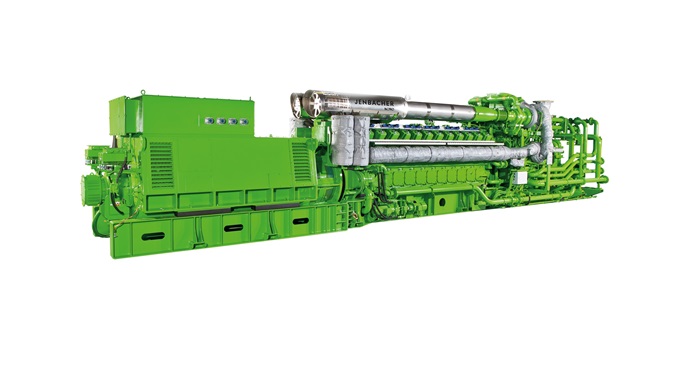

JENBACHER J624 6SERIES Gas combustion engine

- 产品

The crystallization of cutting-edge technology

Based on his rich experience and continuous improvement, Yanbach has developed the 6 series of 1.8 to 4.5 MW reliable internal combustion engine products. Its 1,500 RPM speed increases power generation density and reduces installation costs. The 6 series internal combustion engine is equipped with a precombustion chamber to maximize gas combustion efficiency, while reducing emissions. The proven design and optimized components enable the equipment to operate for 60,000 trouble-free hours prior to overhaul. The all-new J624 is equipped with two-stage turbocharging technology to provide greater efficiency and flexibility in response to changing environments.

Technical characteristics

| Characteristic | Instructions | Advantages |

| Four-valve cylinder head | A central purged precombustion chamber was designed using advanced computational tools and simulation techniques (CFD) |

- Reduce pressure exchange losses |

| Heat recovery | Lubricating oil heat exchanger can be two stage plate heat exchanger |

- Maximum thermal efficiency can be achieved even when the return water temperature is high or fluctuating |

| Air/gas mixer | Before entering the turbocharger, gas and air are mixed under low pressure conditions |

- The main gas supply can be done at low pressure |

| Gas distribution valve | High precision electronic control gas quantitative control valve (natural gas) |

- Quick response, air fuel faster than adaptation |

| Two-stage turbocharging | Latest turbocharging technology (available only) for J624 |

- Improve output power and efficiency |

Technical parameters

| Structure |

V 60° |

|||

|

The cylinder diameter (mm) |

190 |

|||

|

Sstroke (mm) |

220 |

|||

|

Displacement/cylinder (l) |

6.24 |

|||

|

Speed (rpm) |

1,500 (50 Hz) |

|||

|

Average piston speed (m/s) |

11 (1,500rpm ) |

|||

| Scope of supply | Generator set, combined heat and power system | |||

| The available gas | Natural gas, associated gas, biogas, Landfill gas, sewage biogas, special gas, (such as coalbed methane, coke oven gas, wood gas, high temperature cracking gas, etc.) |

|||

| Internal combustion engine model |

J612 |

J616 |

J620 |

J624* |

| Number of cylinders |

12 |

16 |

20 |

24 |

|

The total emissions (l) |

74.9 |

99.8 |

124.8 |

149.7 |

| Dimensions Length × width × height (mm) | ||

| Container configuration | J612–J620 |

12,000/15,000 x 3,000/ 6,000 x 8,100 |

| J624 | 17,000 x 6,000 x 8,400 | |

| Generating set | J612 | 7,600 x 2,200 x 2,800 |

| J616 | 8,300 x 2,200 x 2,800 | |

| J620 | 8,900 x 2,200 x 2,800 | |

| J624* | 12,800 x 2,500 x 2,900 | |

| Cogeneration system | J612 | 7,600 x 2,200 x 2,800 |

| J616 | 8,300 x 2,200 x 2,800 | |

| J620 | 8,900 x 2,200 x 2,800 | |

| J624* | 12,800 x 2,500 x 2,900 | |

|

Empty weight(kg) |

J612 |

J616 |

J620 |

J624* |

| Generating set |

24,000 |

29,200 |

36,900 |

52,100 |

| Cogeneration system |

24,500 |

29,700 |

37,500 |

52,100 |

| Dimensions and weight correspond to 50HZ products | ||||

Output and efficiency

| Natural gas |

1,500 rpm | 50 Hz |

|||||

|

NOx < |

Type |

Pel (kW)1 |

ηel (%)1 |

Pth (kW)² |

ηth (%)² |

ηtot (%) |

|

500mg/Nm3

|

J612 | 2,004 | 45.0 | 1,930 | 43.3 | 88.3 |

| J616 | 2,678 | 45.5 | 2,527 | 42.9 | 88.4 | |

| J620 | 3,360 | 45.6 | 3,172 | 43.0 | 88.6 | |

| J624 | 4,500 | 46.4 | 4,230 | 43.6 | 90.0 | |

|

250mg/Nm3 |

J612 | 2,004 | 44.2 | 1,936 | 42.7 | 86.9 |

| J616 | 2,678 | 44.7 | 2,548 | 42.5 | 87.2 | |

| J620 | 3,360 | 44.8 | 2,977 | 39.7 | 84.4 | |

| J624 | 4,500 | 45.4 | 4,314 | 43.5 | 89.0 | |

| Biogas |

1,500 rpm | 50 Hz |

|||||

|

NOx < |

Type |

Pel (kW)1 |

ηel (%)1 |

Pth (kW)² |

ηth (%)² |

ηtot (%) |

|

500mg/Nm3 |

J612 | 2,000 | 44.4 | 1,827 | 40.6 | 85.0 |

| J616 | 2,676 | 44.6 | 2,433 | 40.5 | 85.1 | |

| J620 | 3,352 | 44.7 | 3,034 | 40.4 | 85.1 | |

|

250mg/Nm3 |

J612 | 1,820 | 43.0 | 1,717 | 40.6 | 83.6 |

| J616 | 2,435 | 43.2 | 2,292 | 40.6 | 83.8 | |

| J620 | 3,054 | 43.3 | 2,863 | 40.6 | 83.9 | |

1) Technical parameters according to ISO3046 standard.

2) The total thermal output error is +/ -8%, the exhaust gas emission temperature is 120˚C, and the biogas emission temperature is 180˚C.

All data is obtained when the equipment is at full capacity and is subject to change and improvement as technology develops.

More models are available upon request

| J624 Two-stage turbo Charged Shanghai International Tourism Resort Shanghai, China | |||||

| Fuel | The unit type | Electric power output | Thermal power output | Dispatch Date |  |

| Natural gas |

5*J624 双级 |

22,000 kW |

20,070 kW |

11/2014 | |

|

Completed in 2014, Shanghai Tourism Resort is a comprehensive resort integrating large-scale entertainment, retail, catering, accommodation and shopping. Disneyland is located in the resort. Gas distribution including 5 Yanbach J624 two-stage turbocharged gas units and other key equipment The energy station provides a variety of clean energy for the core area of the resort, such as cold, heat, electricity and compressed air, in terms of efficiency, energy saving and so on Emission reduction has been greatly improved compared with traditional methods. |

|||||

QUIK LINKS

CONTACT US

ADDRESS : Room 1505, Ruibao Oriental Mansion, Sanyi StreetNo.28-4, Hunnan District, Shenyang, Liaoning Province, China, 110180

PHONE : +86 24-31696477/6479

ADDRESS : No.200 Shifu Road, Heping District Shenyang City, China

PHONE : +86 24-23254798/4799/4800

Wechat scan

Follow the wechat official account