ENGLISH

-

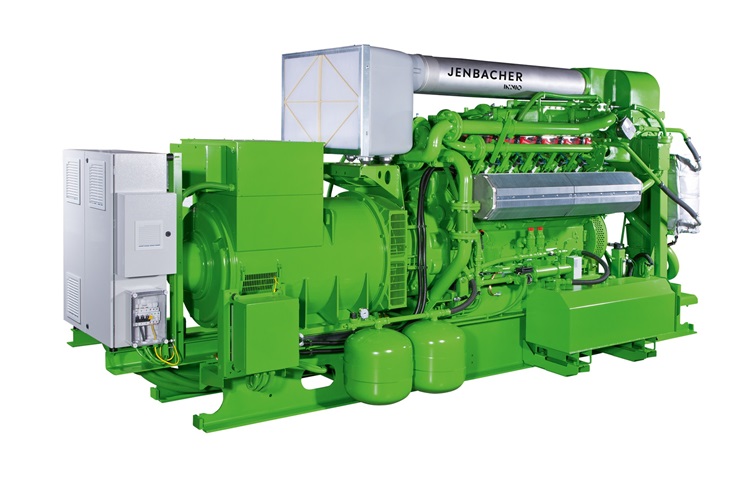

JENBACHER J312 3 series gas combustion engine

- The design concept of long maintenance clearance and easy maintenance of the internal combustion engine and low fuel consumption ensure

-

Efficient, durable and reliable

The design concept of long maintenance clearance and easy maintenance of the internal combustion engine and low fuel consumption ensure the high efficiency of the 3 series gas combustion engine. Optimized component design allows long service gaps even when non-piped gas, such as landfill gas, is used. The series 3 gas combustion engine, with a power range of 500 to 1,100 kW, is highly regarded for its mature technology and high reliability.

Technical parameters

| Structure |

V 70˚ |

||

|

The cylinder diameter (mm) |

135 |

||

|

Stroke (mm) |

170 |

||

|

Displacement/cylinder (l) |

2.43 |

||

|

Speed (rpm) |

1,500 (50 Hz) |

||

|

Average piston speed(m/s) |

8.5 (1,500 rpm) |

||

| Scope of supply | Generator sets, cogeneration systems, Container type generator set/CHP system |

||

| The available gas | Natural gas, associated gas, propane, biogas, Landfill gas, sewage biogas, special gas, (such as coalbed methane, coke oven gas, wood gas, high temperature cracking gas, etc.) |

||

|

Internal combustion engine model |

J312 |

J316 | J320 |

| 12 | 16 | 20 | |

| 29.2 | 38.9 | 48.7 | |

|

Dimensions LxWxH(mm) |

||

| Generating set |

J312 |

4,700 x 1,800 x 2,300 |

|

J316 |

5,200 x 1,800 x 2,300 |

|

|

J320 |

5,700 x 1,700 x 2,300 |

|

| Cogeneration system |

J312 |

4,700 x 2,300 x 2,300 |

|

J316 |

5,300 x 2,300 x 2,300 |

|

|

J320 |

5,700 x 1,900 x 2,300 |

|

| Container |

J312 |

12,200 x 2,500 x 2,600 |

|

J316 |

12,200 x 2,500 x 2,600 |

|

|

J320 |

12,200 x 2,500 x 2,600 |

|

|

Empty weight(kg) |

||

| Generating set |

J312 |

8,100 |

|

J316 |

10,100 |

|

|

J320 |

13,900 |

|

| Cogeneration system |

J312 |

9,500 |

|

J316 |

11,200 |

|

|

J320 |

14,400 |

|

| Natural gas |

1,500 rpm | 50 Hz |

|||||

|

NOx < |

Type |

Pel (kW)1 |

ηel (%)1 |

Pth (kW)² |

ηth (%)² |

ηtot (%) |

|

500mg/m³n |

J312 | 390 | 39.3 | 508 | 51.2 | 90.5 |

| J312 | 598 | 41.1 | 685 | 47.1 | 88.2 | |

| J312 | 635 | 40.8 | 739 | 47.4 | 88.2 | |

| J316 | 851 | 40.7 | 991 | 47.3 | 88.0 | |

| J320 | 1,067 | 40.9 | 1,241 | 47.6 | 88.5 | |

|

250mg/m³n |

J312 | 635 | 39.5 | 766 | 47.6 | 87.1 |

| J316 | 851 | 39.5 | 1,028 | 47.8 | 87.3 | |

| J320 | 1,067 | 39.9 | 1,293 | 48.4 | 88.3 | |

| Biogas |

1,500 rpm | 50 Hz |

|||||

|

NOx < |

Type |

Pel (kW)1 |

ηel (%)1 |

Pth (kW)² |

ηth (%)² |

ηtot (%) |

|

500mg/m³n |

J312 | 548 | 42.0 | 557 | 42.7 | 84.8 |

| J312 | 635 | 40.4 | 709 | 45.1 | 85.5 | |

| J316 | 851 | 40.7 | 935 | 44.7 | 85.4 | |

| J320 | 1,067 | 40.9 | 1,179 | 45.2 | 86.1 | |

|

250mg/m³n |

J312 | 635 | 39.0 | 730 | 44.8 | 83.8 |

| J316 | 851 | 39.3 | 964 | 44.5 | 83.7 | |

| J320 | 1,067 | 39.3 | 1,225 | 45.1 | 84.4 | |

1) Technical parameters according to ISO3046 standard.

2) The total thermal output error is +/ -8%, the exhaust gas emission temperature is 120˚C, and the biogas emission temperature is 180˚C.

All data is obtained when the equipment is at full capacity and is subject to change and improvement as technology develops.

More models are available upon request

Project instance

|

J312 Landfill container Scheme, Italy Cavenago |

|||||

| Fuel | The unit type | Electric power output | Thermal power output | Dispatch Date |  |

| Landfill gas |

2 x J312 |

1,202 kW |

1,494 kW |

09/1999 |

|

|

Each system has its own landfill gas transmission line and waste gas treatment line. The generated electricity is used in the field, and the excess energy is fed into the public grid. The CL.AIR® system enables the exhaust gas to be purified to meet the relevant Italian emission standards. The project features that the heat generated by the generator unit is not only used for landfill leachate treatment, but also used to heat the greenhouse. |

|||||

*Indicates a trademark of the General Electric Company

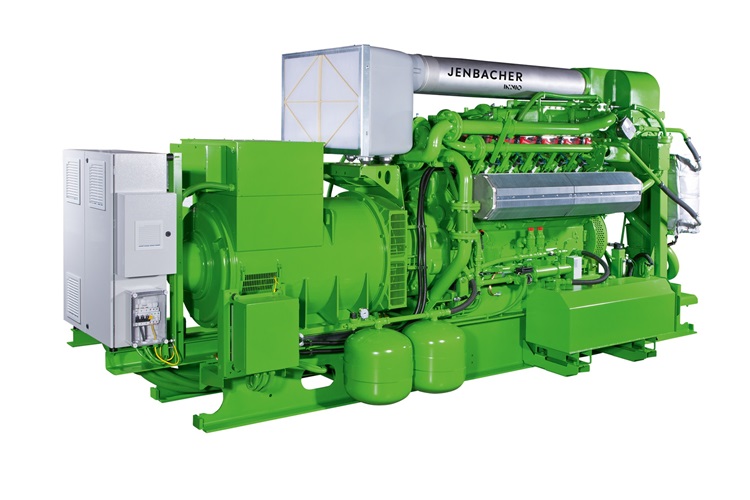

JENBACHER J312 3 series gas combustion engine

- 产品

Efficient, durable and reliable

The design concept of long maintenance clearance and easy maintenance of the internal combustion engine and low fuel consumption ensure the high efficiency of the 3 series gas combustion engine. Optimized component design allows long service gaps even when non-piped gas, such as landfill gas, is used. The series 3 gas combustion engine, with a power range of 500 to 1,100 kW, is highly regarded for its mature technology and high reliability.

Technical parameters

| Structure |

V 70˚ |

||

|

The cylinder diameter (mm) |

135 |

||

|

Stroke (mm) |

170 |

||

|

Displacement/cylinder (l) |

2.43 |

||

|

Speed (rpm) |

1,500 (50 Hz) |

||

|

Average piston speed(m/s) |

8.5 (1,500 rpm) |

||

| Scope of supply | Generator sets, cogeneration systems, Container type generator set/CHP system |

||

| The available gas | Natural gas, associated gas, propane, biogas, Landfill gas, sewage biogas, special gas, (such as coalbed methane, coke oven gas, wood gas, high temperature cracking gas, etc.) |

||

|

Internal combustion engine model |

J312 |

J316 | J320 |

| 12 | 16 | 20 | |

| 29.2 | 38.9 | 48.7 | |

|

Dimensions LxWxH(mm) |

||

| Generating set |

J312 |

4,700 x 1,800 x 2,300 |

|

J316 |

5,200 x 1,800 x 2,300 |

|

|

J320 |

5,700 x 1,700 x 2,300 |

|

| Cogeneration system |

J312 |

4,700 x 2,300 x 2,300 |

|

J316 |

5,300 x 2,300 x 2,300 |

|

|

J320 |

5,700 x 1,900 x 2,300 |

|

| Container |

J312 |

12,200 x 2,500 x 2,600 |

|

J316 |

12,200 x 2,500 x 2,600 |

|

|

J320 |

12,200 x 2,500 x 2,600 |

|

|

Empty weight(kg) |

||

| Generating set |

J312 |

8,100 |

|

J316 |

10,100 |

|

|

J320 |

13,900 |

|

| Cogeneration system |

J312 |

9,500 |

|

J316 |

11,200 |

|

|

J320 |

14,400 |

|

| Natural gas |

1,500 rpm | 50 Hz |

|||||

|

NOx < |

Type |

Pel (kW)1 |

ηel (%)1 |

Pth (kW)² |

ηth (%)² |

ηtot (%) |

|

500mg/m³n |

J312 | 390 | 39.3 | 508 | 51.2 | 90.5 |

| J312 | 598 | 41.1 | 685 | 47.1 | 88.2 | |

| J312 | 635 | 40.8 | 739 | 47.4 | 88.2 | |

| J316 | 851 | 40.7 | 991 | 47.3 | 88.0 | |

| J320 | 1,067 | 40.9 | 1,241 | 47.6 | 88.5 | |

|

250mg/m³n |

J312 | 635 | 39.5 | 766 | 47.6 | 87.1 |

| J316 | 851 | 39.5 | 1,028 | 47.8 | 87.3 | |

| J320 | 1,067 | 39.9 | 1,293 | 48.4 | 88.3 | |

| Biogas |

1,500 rpm | 50 Hz |

|||||

|

NOx < |

Type |

Pel (kW)1 |

ηel (%)1 |

Pth (kW)² |

ηth (%)² |

ηtot (%) |

|

500mg/m³n |

J312 | 548 | 42.0 | 557 | 42.7 | 84.8 |

| J312 | 635 | 40.4 | 709 | 45.1 | 85.5 | |

| J316 | 851 | 40.7 | 935 | 44.7 | 85.4 | |

| J320 | 1,067 | 40.9 | 1,179 | 45.2 | 86.1 | |

|

250mg/m³n |

J312 | 635 | 39.0 | 730 | 44.8 | 83.8 |

| J316 | 851 | 39.3 | 964 | 44.5 | 83.7 | |

| J320 | 1,067 | 39.3 | 1,225 | 45.1 | 84.4 | |

1) Technical parameters according to ISO3046 standard.

2) The total thermal output error is +/ -8%, the exhaust gas emission temperature is 120˚C, and the biogas emission temperature is 180˚C.

All data is obtained when the equipment is at full capacity and is subject to change and improvement as technology develops.

More models are available upon request

Project instance

|

J312 Landfill container Scheme, Italy Cavenago |

|||||

| Fuel | The unit type | Electric power output | Thermal power output | Dispatch Date |  |

| Landfill gas |

2 x J312 |

1,202 kW |

1,494 kW |

09/1999 |

|

|

Each system has its own landfill gas transmission line and waste gas treatment line. The generated electricity is used in the field, and the excess energy is fed into the public grid. The CL.AIR® system enables the exhaust gas to be purified to meet the relevant Italian emission standards. The project features that the heat generated by the generator unit is not only used for landfill leachate treatment, but also used to heat the greenhouse. |

|||||

*Indicates a trademark of the General Electric Company

QUIK LINKS

CONTACT US

ADDRESS : Room 1505, Ruibao Oriental Mansion, Sanyi StreetNo.28-4, Hunnan District, Shenyang, Liaoning Province, China, 110180

PHONE : +86 24-31696477/6479

ADDRESS : No.200 Shifu Road, Heping District Shenyang City, China

PHONE : +86 24-23254798/4799/4800

Wechat scan

Follow the wechat official account